Micro Devices Facility

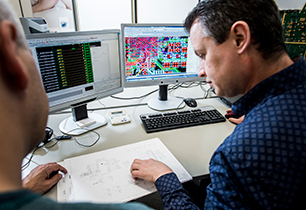

You have a high-tech, complex idea or concept which requires a custom microsystem solution and you are looking for technical verification and validation. Can it be made? Reliably? How best to decide between conflicting Micro Devices requirements? You want to make the best decision because about 80% of your key product properties like manufacturability, cost price and reliability are defined in the development phase.

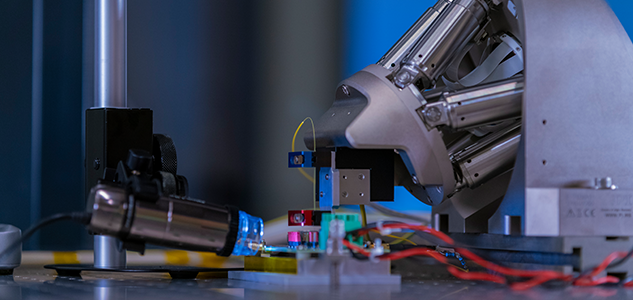

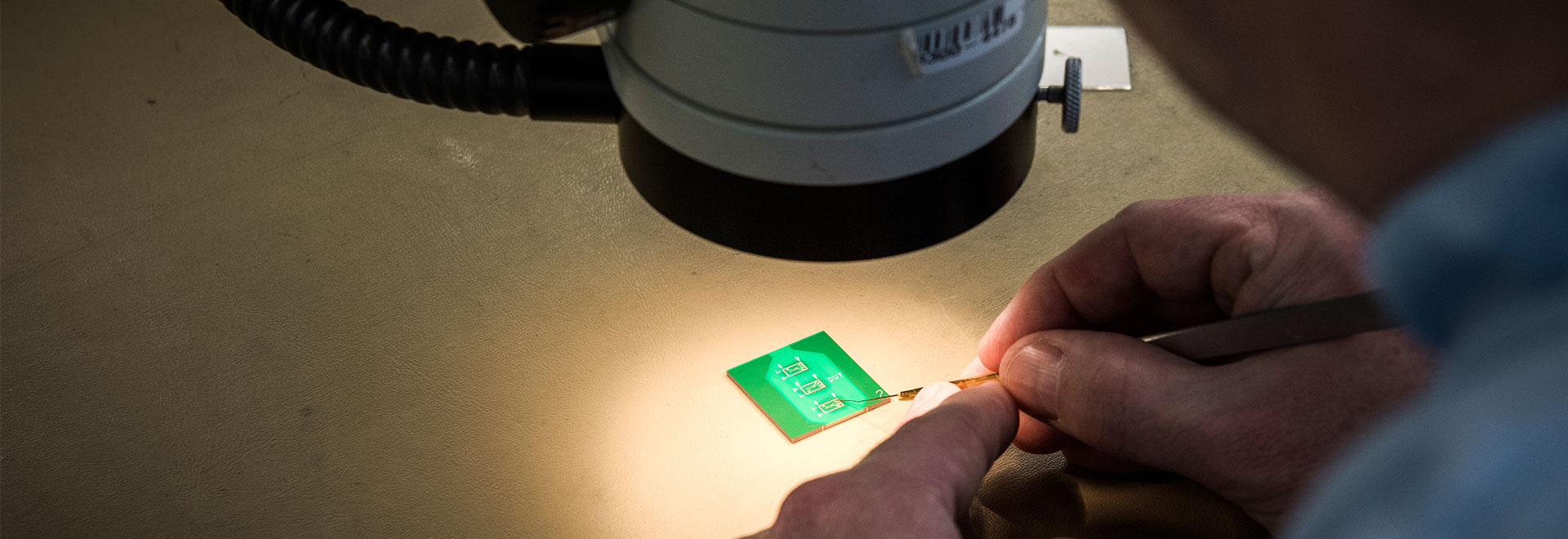

Assembly and integration of microsystem modules into devices

Fitting all conflicting requirements in a manufacturable microsystem module? This is what Philips Engineering Solutions Micro Devices Facility The Greenhouse is about. We deliver key microsystem modules, integrated into devices, for the health-tech & high-tech markets. Customers typically require a complex combination of technologies to obtain new advanced functions at small scales.

Challenges in Micro Devices

Micro Devices challenges often become apparent in concept & development phase: how to fit increasing functionality into a manufacturable design, overcoming seemingly conflicting processes and material incompatibilities. This is our expertise! An expertise that stems from working with Philips Research and many industry leaders. We have over 40 years of experience in micro-assembly prototyping, new product introduction and volume manufacturing.

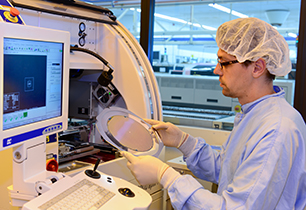

From Micro Devices prototyping to volume production

Our micro-assembly line is fit for prototyping as well as volume production. With our know-how, experience, and systematic approach, we support you in developing and making devices – like test and demo boards – to developing your products from prototype to high-quality products, and producing them with high yield and in high quantities. Our ISO 9001 and ISO 13485 certification enables us to run high-tech and health-tech projects in a controlled manner. We work with standard process flows, highly skilled people, and a broad range of test and inspection equipment to assure that the high quality of your products is guaranteed. We are certified for:

ISO 9001:2015 ISO 14001:2015 ISO 13485:2016

Micro Devices services

We team up with you to make your product within the critical time path, reacting fast and flexible on new insights. We assure integral coupling with supply chain and manufacturing activities. We facilitate complex Micro Devices integrations by working with innovative interconnect technologies and unconventional combinations of existing ones while securing that designs can be manufactured in low and high volumes.

Micro Devices key application areas

Photonics development and industrialization

In house expertise to shorten your photonics development time and help you achieve consistent products at volume scale.

Micro-assembly for RF applications

RF application design: modeling & simulation, layout, thermal management, EMC, antenna design, signal integrity, wireless reliability, functional testing.

What our partners value

Capabilities for

MEMS & Micro Devices

- Micro-assembly: die attach, wire-bonding, stud bumping, ACF bonding, pick & place and soldering

- Concept creation and technology scoping

- Continuous improvement

- Cpk analysis and yield improvement

- DfX: Design for eXcellence

- Functional testing

- Inspection and failure analysis: solder paste inspection, 3D automated optical, X-ray

- Integrated MEMS with ASIC design

- Mentor graphics lay-outing

- Microsystem and board design

- Risk management, FMEA

- Supply chain management

- TPD/DMR product documentation management

- Verification & validation of process and tooling

- State-of-the-art industrial PCB assembly

Download the presentations to know more about our capabilities

More information about our Micro Devices Facility

Contact us about our micro devices facility

Philips Engineering Solutions

Micro Devices Facility

The Greenhouse

Kastanjelaan 400, building SFH

5616 LZ Eindhoven

Netherlands