BioMEMS

How to succeed in Next-Generation Sequencing and Point-of-Care diagnostics with BioMEMS?

BioMEMS in healthcare

As a biotech pioneer, your company’s unique understanding of how cells work at the molecular level has the potential to revolutionize healthcare. From next-generation sequencing (NGS) and drug delivery systems to Point-of-Care diagnostics and precision microtools. All based on the exciting capabilities of BioMEMS (micro-electro-mechanical systems) technologies and applications.

From proof-of-principle to manufacturing

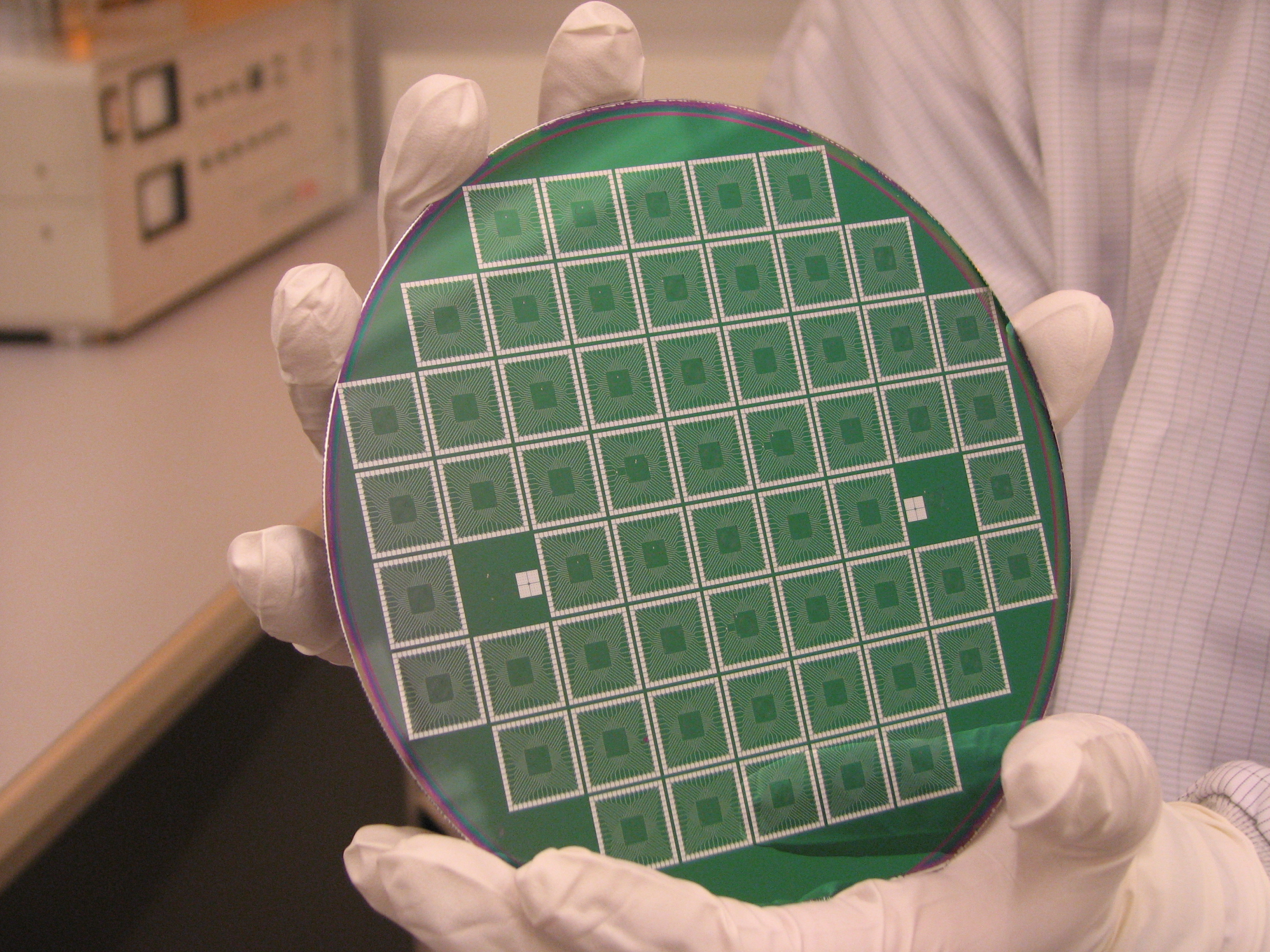

Developing BioMEMS devices from proof-of-principle to manufacturing at scale requires a profound understanding of how physical and biological components work at the submillimeter level.

You need designs that meet submillimeter tolerances, tools that create submillimeter structures and a submillimeter manufacturing process that delivers uniform, medical-grade products at industrial scale.

With Innovation Engineering, you benefit from unique BioMEMS expertise that has helped leading BioMEMS companies successfully turn their imaginative ideas into working devices.

What are BioMEMS?

BioMEMS – Biomedical micro-electro-mechanical systems – have considerable overlap with lab-on-a-chip (LOC). Traditional microfluidics are used as lab-on-a-chip or Micro-total analysis systems (uTAS), for chemical analysis and/or reaction. BioMEMS involve measuring, adapting or even delivering biological functions. High potential applications include Next-Generation Sequencing of DNA (NGS) and Point-of-Care diagnostics.

Direct contact

Elena Beletkaia

Business Development Manager

Pure precision for high throughput sequencing

Creating devices

When you are creating a massive parallel screening device that can process thousands or millions of sequences concurrently, any deviation in the structure of individual microfluidic features will cause your design to fail.

Manufacturing devices

Our BioMEMS expertise and novel techniques for developing high throughput screening methods deliver the precision you need. This results in devices that can reliably read out large numbers of biological components, e.g. DNA, cells, organ(oid)s.

We manufacture devices with small and tightly controlled structures to guide, manipulate and measure complex fluids, particles and droplets.

Real-world examples of BioMEMS devices

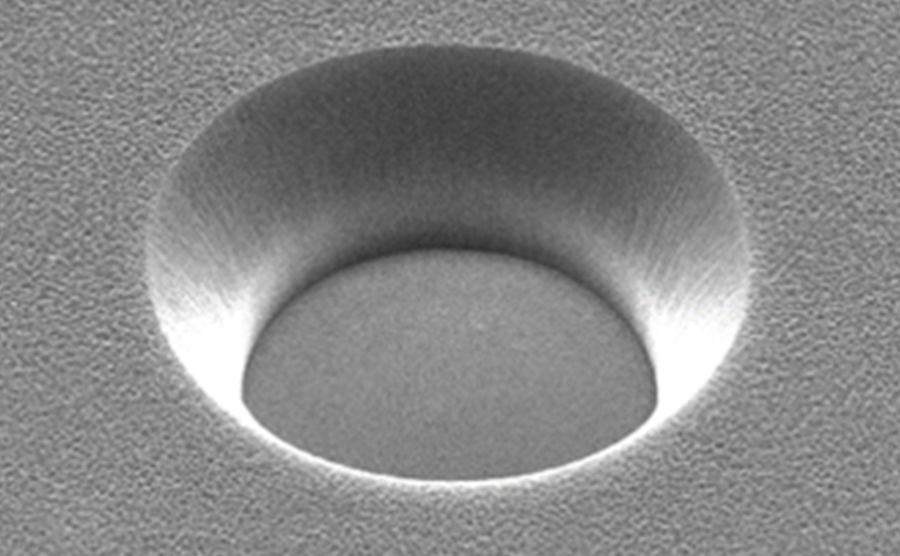

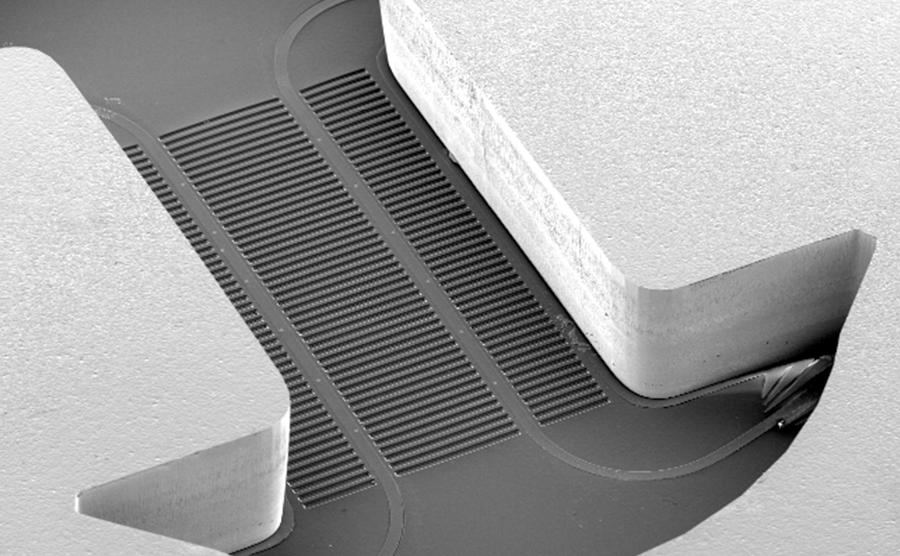

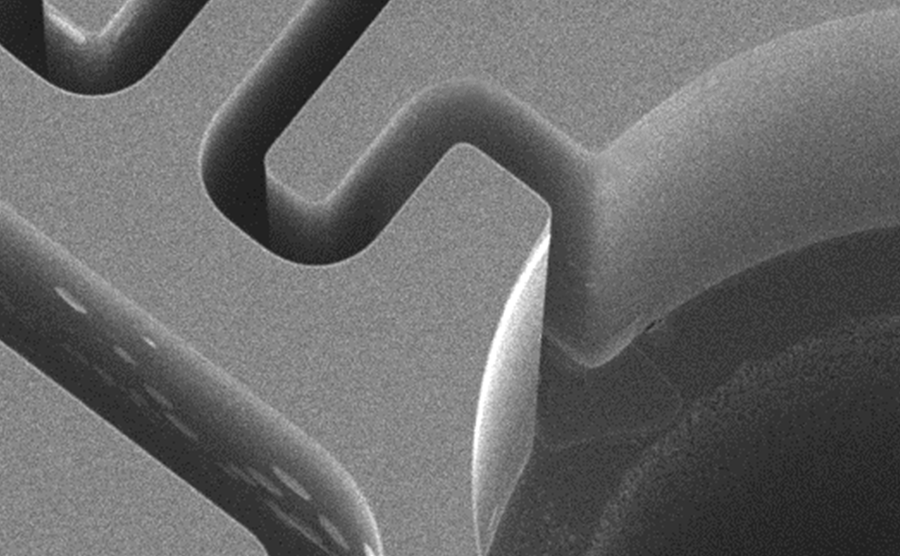

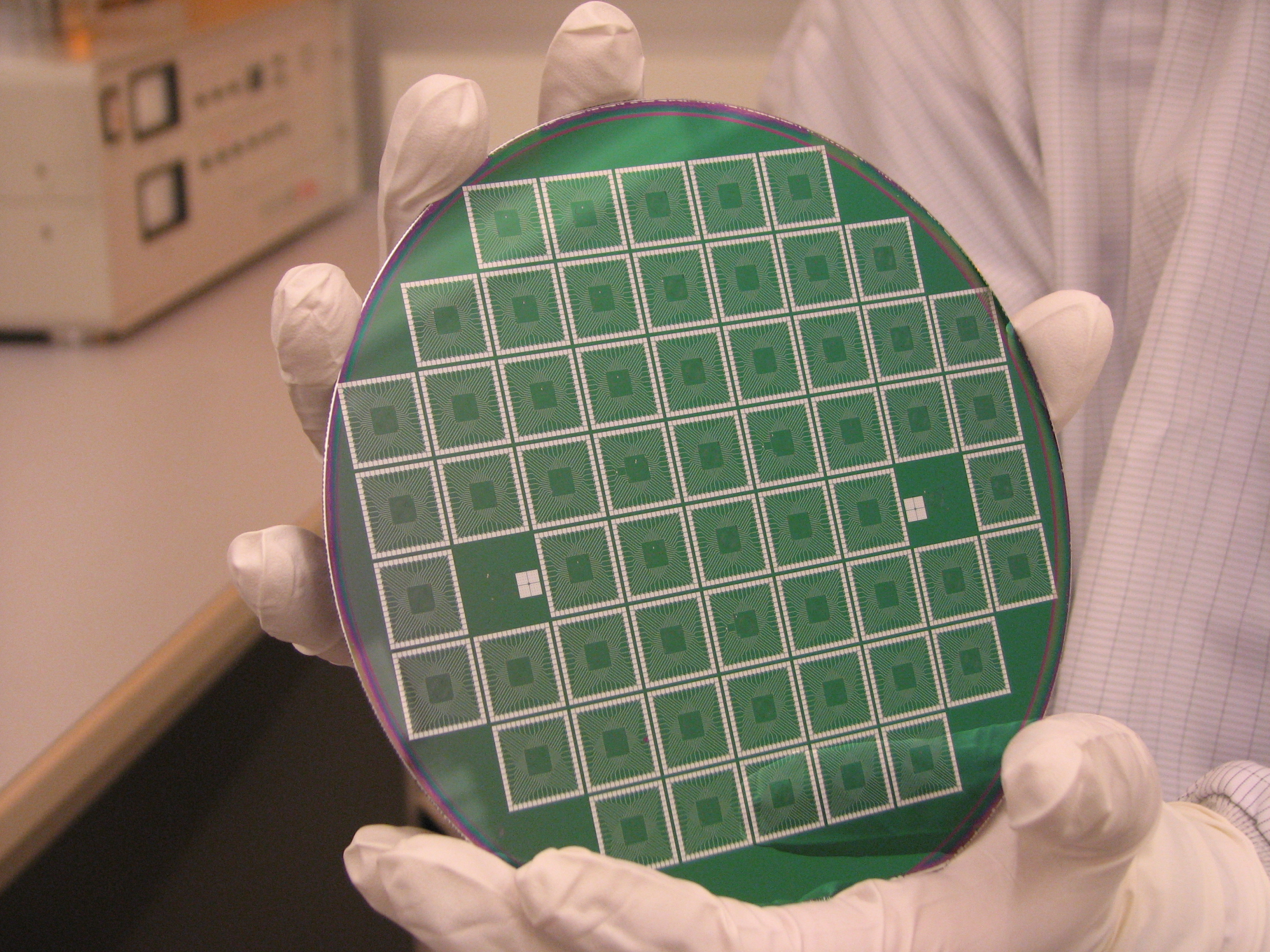

Our state-of-the-art tool set enables us to create microfluidic structures with superb control over critical dimensions in a range of substrate materials. These following BioMEMS applications have benefited from our expertise.

Advantages of BioMEMS technologies

BioMEMS are micro-electro-mechanical systems (MEMS) that offer numerous advantages for biomedical applications. They are improving accuracy, speed, and cost-efficiency for next-generation DNA sequencing technologies.

For example, by replicating human physiological factors, organ-on-a-chip devices will drive the development of new medicines and reduce the need for animal testing. Another example is the downscaling of lab processes to chip format by Micro-total analysis systems (µTAS) or lab-on-a-chip (LOC) devices. This redefines automation, throughput, and accessibility for diverse applications.

Our experience with processing novel materials, advanced molding, microfluidics, and assembly technologies can help you make the right choices in developing and manufacturing your BioMEMS applications and technologies.

Unique technical capabilities for BioMEMS:

- Deep Reactive Ion Etching in silicon

Many micro-devices in the BioMEMS domain have micron features with very tight specifications. DRIE etching at our MEMS Foundry is done in highly controlled conditions by our etching experts. It delivers the highest quality during development and maintains that standard during manufacturing. Our feature and slope control are world class.

- Noble Metal deposition and etching

In highly parallelized readouts of diagnostic devices, large numbers of thin electrodes need to connect the measuring volume to a CMOS chip. For example, in our MEMS foundry, we can process this on-top-of-CMOS, yielding an even higher integration between device and (digital) readout. Besides noble metals e.g. Au and Pt, we can also process a wide variety of materials e.g. Ti and Al. The ability to deposit and etch Platinum (Pt) is unique.

- Microassembly of chips into devices

At our Micro Devices facility, we can place and connect chips with CMOS and other circuits on your prototype using sophisticated electronic assembly processes, including flip-chip, pick-and-place and wire-bonding. Our micro-assembly line is ISO 9001 and ISO 13485 certified and meets the latest quality standards. This approach to prototype assembly guarantees a manufacturable and transferrable process right through to market launch and volume manufacturing.

How we can shorten your BioMEMS development time and improve results

The earlier you identify a potential issue in your BioMEMS concept, the more time and money you will save and the greater your chances of success are.

Micro device challenges often become apparent in the concept and development phase: how to fit more functionality into a manufacturable design, overcoming potential process and material issues, etc. We can help. Our expertise stems from our long collaborations with Philips Research and many other industry leaders. We have over 40 years of experience in micro-assembly prototyping, new product introduction and volume manufacturing. Our services include:

Based on your initial ideas or ‘proof-of-principle,’ we can work with your team to set-up the required specifications, and select process steps and strategies to ensure an industrializable process flow. This supports you in maintaining the irght quality when manufacturing at volume. When needed this can be done at medical grade and compliant with ISO 13485.

Based on your concept process flow, we can start the BioMEMS process development with short loops for the most critical steps in the process. At each stage, a proper pFMEA (process Failure Modes and Effect Analysis) can be done on the results. We define what is critical to meet your quality requirements and this serves as input for the next phase. The concept phase can yield the first feasibility batches to confirm the feasibility of the process flow (proof-of-concept) when this is within the scope of the project.

Flex-to-rigid (F2R) for BioMEMS

Many BioMEMS applications require geometry, especially fluidical-electrical applications. F2R offers opportunities to do so.

Let us help with your BioMEMS challenges

Elena Beletkaia

Business Development Manager

Learn more about our services

Our Microfluidic experts are here to think along with you and accelerate your innovation with clever approaches in the design and manufacturing of Microfluidic devices.

More about Microfluidic Devices

Our 140 experts design, develop and manufacture custom microelectromechanical systems (MEMS) and assemble micro devices. We follow a phase-gated approach; from demonstrating feasibility and giving proof of concept, up to manufacturing your devices with the right quality.