It’s a small step from rocket science to health technology

To our engineering teams, the words ‘it cannot be done’ work like a magic charm. They take pride in solving the seemingly impossible. In the interview series ‘Our eureka moment’, engineers talk about these breakthroughs; what challenges did they face and how did they overcome them, together with their colleagues?

Rocket science, in popular language, is often referred to in two ways.

‘This is no rocket science’ means that something is not extremely difficult or challenging.

If someone calls you a ‘rocket scientist’, it is quite a compliment of your technical abilities.

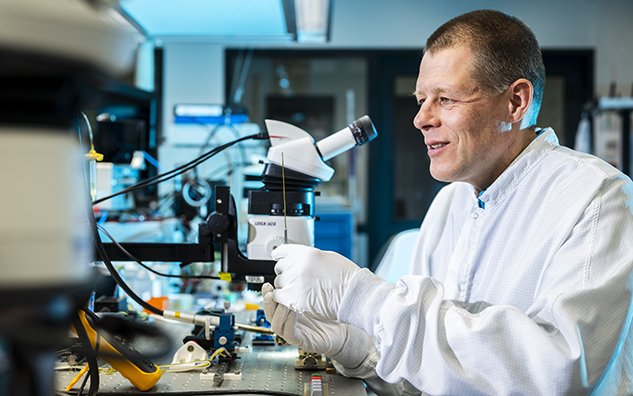

Jaap van der Meulen is somebody who is actually a rocket scientist, although the term aerospace engineer is more accurate. In fact, the start engine of a rocket that he worked on some twenty years ago, is about to set off to space. As a Senior Project Manager within Philips, he now oversees teams that develop medical technologies.

In Jaap’s experience, the step from aerospace to health technology is smaller than you might think.

Ariane 6

In the last quarter of 2023, the European Space Agency expects to launch Ariane 6 into space. Its upper stage start engine is unique, says Jaap: “It is re-ignitable, which means it can be turned on and off again. The initial launch will propel the rocket to a height of approximately 200 kilometers in ten minutes. Then, the upper stage engine will burn, which helps the payload (satellite) to reach the targeted orbit around the planet. By having multiple re-ignitions of the upper stage, multiple satellites can reach multiple orbits, which lowers the launch cost per satellite.”

Working on this start engine was his first experience as a systems engineer: “This role means overseeing the whole process. We had a team consisting of several specialists, like mechanical designers and assembly experts. As a systems engineer, you tie everything together and you are responsible for the process, for the development of the system as a whole.”

Building in the ability of the start engine to reignite was just one of the challenges that the team managed to overcome: “As you can imagine, developing a rocket engine is quite costly. It requires a lot of testing. And for each test you need to build a new start engine, which costs tens of thousands of euros. Our team developed a workaround; a robust model of a start engine that could be used to perform tests, but which would not be destroyed during the test. This reduced the cost of each test with more than a factor ten.”

“The level of precision is sometimes astounding. You can make a capsule land precisely on the center spot of a football stadium.”

Jaap van der Meulen, Senior Project Manager

Astounding precision levels

The twenty years between his work on the start engine and its actual launch demonstrates that development cycles in aerospace engineering can be long. “The level of precision is sometimes astounding. As a research assistant on the University of Stuttgart I worked on a research project on bringing back a capsule to earth. It is hard to imagine the complexity of calculating the exact landing spot, taking into account all factors including speed, timing, the shape of the earth, and the unpredictable composition of the atmosphere. If you do it right, you can make such a capsule land precisely on the center spot of a football stadium.”

As a senior project manager in Philips, Jaap oversees a team of specialists that develop medical devices including micro-electrical mechanical systems (MEMS); “There is actually quite a bit of overlap between aerospace engineering and medical engineering. One is that it is crucial to reduce risks. In aerospace, if you make a mistake, you might blow up hundreds of millions. In medical technology, you might jeopardize patients’ lives.”

The Ariane 5, a predecessor of the Ariane 6, actually exploded after launch. “This was due to a failure in the software that was used to determine the horizontal velocity of the rocket. Even back in those days, in the nineties, it was hardly rocket science, but the code was too easily copied from an earlier version.”

“There are no shortcuts”

This illustrates another aspect that aerospace engineering and medical technology have in common. Jaap: “There are no shortcuts. You need to think things through, do it first-time right. If you move on too quickly, you will regret it later on.

The development methods in both industries are basically the same. You start by defining business requirements, that translate to user, product and functional requirements; what should the technology actually do? Once you know this, you can start working on parts and on how they should work together. Finally, you need to verify, validate and test. Some of the vibration tests that I performed in aerospace engineering do not differ that much from the ones that we do at Philips.”

“There are no shortcuts. You need to think things through, do it first-time right. If you move on too quickly, you will regret it later on.”

Jaap van der Meulen, Senior Project Manager

One of the projects that Jaap worked on, was an ultrasound needle tip that is used in image-guided therapy to follow the location of a needle into a body. “I really think that what we do here at Philips is world class technological development, with an enormous impact on people’s lives. It’s high level, challenging and rewarding at the same time.”

When the Ariane 6 will be launched exactly is still a bit uncertain. But Jaap hopes that he can physically attend this exciting event. “We have always stayed in touch, in 2015 I came back for temporary support in project management. I really hope that we can watch the event together, in French Guiana, holding a glass of champagne. After all, a lot of our passion, blood, sweat and tears went into this start engine.”